If you keep in mind a few rules, make regular checks and carry out simple measures, your tire will remain in good condition for a long time.

This particularly involves keeping an eye on the pressure, checking for wear and storing tires properly.

Also bear in mind that it is always better to fit new tires (or the least worn) on the rear wheels.

Having your tires correctly inflated not only optimizes performance, but also leads to increased safety. You should therefore check the pressure of your tires (not forgetting the spare tire) at least once a month and before long journeys.

The first step is knowing what your tire pressure should be. You can find out what your vehicle’s tire pressure should be by looking in your vehicle owner’s manual or on the little sticker on the inside of your driver’s side car door for the recommended PSI.

1) Purchase a certified air pressure gauge or take your vehicle to a nearby service center (or gas station) for a check-up.

2) Tires must be checked in a “cold” state (at least three hours after driving).

3) Insert the gauge into the valve.

4) Compare the measured air pressure level with the level listed on the car door.

- in case of higher pressure than a recommendation, deflate your tire to the recommended pressure.

- in case of lower pressure than a recommendation, inflate your tire up to the recommended pressure.

But this period depends on a variety of factors including driver behavior, the roughness of the road surface, the mechanical condition of the vehicle and tire pressure. The major risk is the loss of adhesion on wet ground, if the remaining tread can no longer evacuate water in the contact with the road.

Tread wear indicators, built into the main tread grooves, show the tread depth. A tire must be changed as soon as it wears down to these indications. Tread depth remaining is then 1.6 mm, which corresponds to the legal minimum. Checking tires for wear also involves getting them checked regularly, both inside and outside, by a tire specialist.

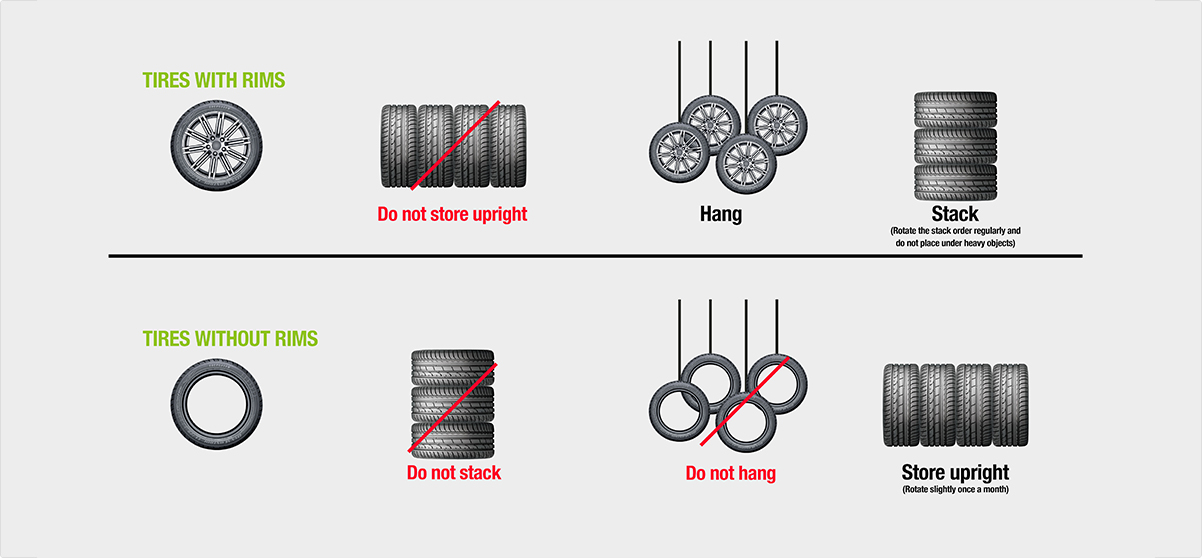

Tires age even when they're not being used. Surface cracks appear in the rubber and the carcass can distort. Proper storage increases the life expectancy and performance of tires. A few basic rules need to be followed.

Storage guidelines vary, depending on whether your tires are mounted on rims or not (see the diagram below)

Due to their circular design, tires should have even wear on contact areas. However, in reality, irregular tire wear is common. Uneven wear shortens tread life and can cause abnormal shaking in the vehicle. Causes of irregular wear include driving style, poorly serviced vehicle, incorrect air pressure and lax tire rotation among others.

Tire Rotation

Even wear on all tires eliminates the need for tire rotation. However, when irregular wear is detected, tires must immediately be rotated. To prevent such uneven wear in advance, switching the location of tires is recommended every 7,500miles. In the case of snow tires which use spike pins, care must be taken not to change the rotational direction of the tires as the failure to do so may result in the loss of spikes.

Tread wear indicator

Tires have built-in tread wear indicators which mark the minimum allowable tread depth. The indicators are 4~6 small raised bars which run across the grooves of the tire tread and are 1.6mm in height. Made to be clearly visible to consumers, the mark in the shoulder area also helps to pinpoint the location of the indicators. When measuring tread depth, one should avoid the area with the indicators.Tires with worn out treads lack the ability to channel water, creating extremely dangerous situations such as slipping or hydroplaning on wet roads. Tire blow outs also increase in frequency.

This ensures better control and handling in situations of emergency braking or on tight bends, particularly on wet surfaces. The loss of rear wheel grip is not easy to be controlled by the driver. On a bend, this means that the car oversteers and the rear of the vehicle starts to skid. Drivers are tempted to brake and turn the wheel too hard… and they end up going into a spin! Only an experienced driver would have the reflex to do the opposite, namely countersteer and accelerate. Loss of front wheel grip (understeering) is easier to correct with the steering wheel, whilst taking your foot off the accelerator. Fitting the best tires at the rear, the driver enjoys a substantial gain in safety.

Below this temperature, the rubber of a summer tire hardens and becomes less effective. In winter, weather conditions are radically different and braking distances can be multiplied by 8 depending on the type of road. A winter tire offers better grip, traction and safety by reducing braking distances.

Winter tires differ from summer tires through the chemical composition of their rubber, which has a formula that enables them to remain flexible at low temperatures for better grip on slippery surfaces (rain, snow and ice).

The tread design also differs in that they have a greater number of sipes and a chunky tread pattern. Snow and ice traction is improved and there is a reduced risk of hydroplaning.

For optimal safety, you are strongly advised to fit 4 winter tires. If you only fit 2 on the drive wheels, traction on start-up is fine, but grip is not balanced between the front and rear axle. With the winter tires fitted on the front axle of a front-wheel drive, the vehicle may spin or skid in bends. With the tires fitted on the rear axle of a rear-wheel drive, the vehicle may fail to turn and go off the road in curves.

Specific legislation exists in different countries as regards to winter tires.

Tire Balance

Tire balancing compensates for the weight of the tire and wheel assembly after the tire is mounted. A wheel is out of balance when one area is heavier or lighter than the rest. The result of bouncing or wobbling, which can decrease treadwear, increase vibration and cause stress on your vehicle. The balance correction weights are added to counterbalance the tires.

When to Balance

A tire is replaced.

A balance weight is moved or removed.

You purchase new tires.

To balance a wheel, your mechanic uses a balancing machine to determine where the heavy spots are. Weights are then attached to the exterior or interior of the wheel to counteract centrifugal forces acting on the heavy areas when the wheel is turning. This will eliminate vertical bouncing and side-to-side wobble.

This delicate operation consists of assembling a unit comprising a wheel, a tire and a valve, not forgetting the air for inflation. Any operation achieved to a professional guarantees scrupulous compliance with the instructions specified by tire manufacturers, vehicule manufacturers and legislation.

He will be able to detect any anomalies liable to affect your safety.

It's difficult to tell if your wheels and axles are correctly aligned while driving. But if your vehicle's suspension geometry is incorrect, its handling may be altered and your safety compromised. If your tire has come into contact with a solid object, such as a kerb or pothole, or you have noticed uneven wear on your tires, please go to a tire specialist to have it thoroughly inspected. It's important to ensure correct alignment to get the best road handling, to protect your tires from irregular and/or rapid wear and to save fuel.

A well balanced tire, with an even distribution of weight, rotates on its axle without causing any vibrations. For perfect balancing, weights are placed at certain points around the rim. This can only be carried out by specialists, as it requires specific measuring equipment. Well-balanced tires make for more comfortable driving, longer tire life and less premature mechanical wear.

To ensure tire sealing, the rim must not be distorted or rusted. When fitting, the beads must be properly positioned on the rim. The valve and its cap must be changed every time it is fitted.

Whether a small perforation or a large puncture resulting in a significant loss in pressure, your tire must be inspected by a qualified tire expert. Only a professional will be able to ascertain whether the inner casing has been damaged, making the tire impossible to repair.

Always consider your safety and that of your passengers. If you can, stop your vehicle in a safe place, away from the traffic.

Apply your handbrake.

Switch off the engine and put the car into gear.

Switch on your warning lights.

Put on your reflective safety vest.

Place your warning triangle at the required distance behind your car.

Take care when rejoining the flow of traffic. Remember to switch off your warning lights. Stop at the first service station to check the air pressure of the spare tire. Tighten the nuts as much as you can. Insufficiently tightened nuts can damage the brake discs or distort the balance of the wheels.